Some Of Dust Extractors For Small Workshops

Table of ContentsThe Main Principles Of Dust Extractors For Small Workshops Dust Extractors For Small Workshops for BeginnersSome Ideas on Dust Extractors For Small Workshops You Should KnowThe Facts About Dust Extractors For Small Workshops Revealed

The obstacles for shop dirt collection systems focus on crystalline silica dirt, carbon monoxide gas, as well as warmth, which are poisonous mixes. These factors make meeting air top quality criteria tough and also requiring. Consequently, when picking a dirt control system for a factory, the very first consideration is the capacity of the device to endure extreme and also harmful workplace problems.

Covering, or thermal spray, applies warmed material to steels to layer their surface areas. Dust collection systems for this sort of operation should be particularly made to fit the sort of coating being applied. The objective of the system is to regulate and also minimize overspray and also dirt. The normal thermal spray dust control system utilizes ducts to relocate air to the collection tool. dust extractors for small workshops.

It would certainly seem likely to boost air flow as well as movement, this kind of option may be ineffective and also waste energy. The layout of the booth depends on the pressure of the air entering the cell or booth. For most systems, it is very important to have a small vacuum cleaner in the cubicle to stay clear of feasible favorable pressure.

All About Dust Extractors For Small Workshops

Another technique is merely positioning the make-up air link on the top of the booth. Despite the design, it is crucial for the cleaning of the air to have cross air flow. A lot like a cleanroom, air movement in a thermal spray cubicle can be either straight or downward, though the descending layout is best for dirt collection systems.

The pharmaceutical sector is a highly controlled industry with comprehensive and exact guidelines. Dust from drugs is created primarily throughout the production as well as packaging of items. Each action of creating a medication, which includes granulating, drying, blending, pushing, layer, as well as grinding, creates big amounts of dust that need to be gotten rid of.

Obstructing as well as controlling this circulation is the feature of the dirt control system. When creating a dust control system for a pharmaceutical plant, the first factor to consider is mapping the air flow click to find out more system to track the course of dirt, fumes, existing airflow patterns, and also possible evolutionary changes. Because many pharmaceutical dirts are flammable, the layout of the ventilation system is extremely vital.

HEPA filters are frequently discovered in pharmaceutical dirt control systems given that they are one of the most reliable as well as reliable. Similar to a factory system, they are mounted as a second protection to attain zero exhausts. Reusing creates a good deal of dirt as an all-natural result of reducing items to their basic materials.

An Unbiased View of Dust Extractors For Small Workshops

Dirt originates after products are shredded, squashed, or have paint or lacquer got rid of. All reusing facilities are needed to abide by air quality standards. As they function to fulfill high quality standards and control contaminants, they have actually identified that dirt control is a significant issue, leading to the vast use dirt collection systems to alleviate as well as have the problem. dust extractors for small workshops.

When manufacturers choose a dirt control system, they are encouraged by producers about the kind of system that would certainly best fit their requirements since buying as well as mounting a dirt control system is a major investment. Particulate issue is available in a variety of types, from silicon dust to wood chips as well as sawdust.

The Definitive Guide for Dust Extractors For Small Workshops

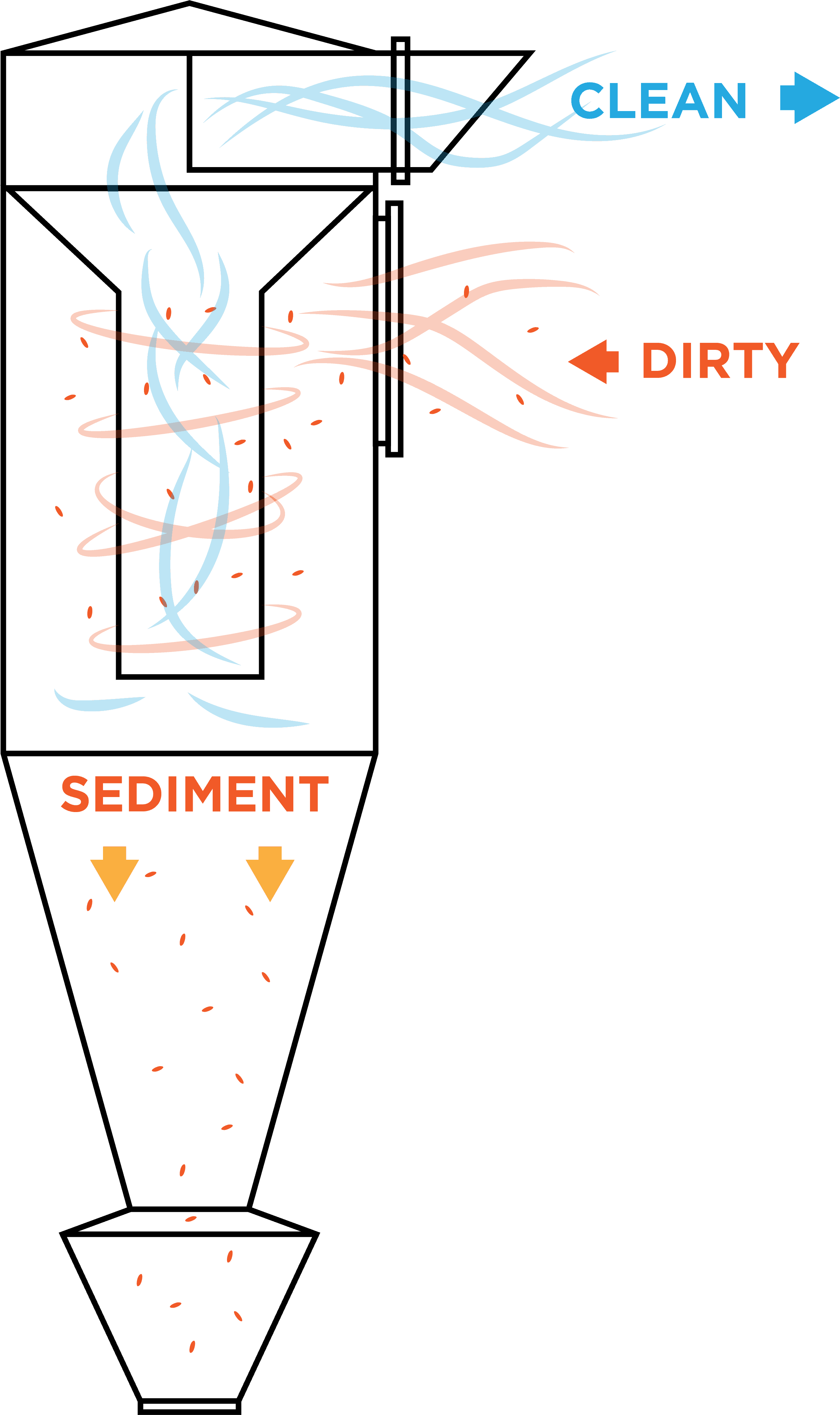

Material filter bags in a cartridge system are the most effective technique for gathering dust. Dust collection systems are covered to have the dust as well as clean the air.

Plastic Dust High-Density Polyethylene (HDPE) dust is generated in the manufacturing of plastic panels when they are designed as well as developed on an edge leaner, mill, or miter saw. Paper Dust One of the much more this article usual kinds of dust is paper dust, the side result of the production of different kinds of paper.

With the intro of dust collection systems, employees are much safer and extra secured. Sugar Sugar dust is the by-product of the manufacturing of candy. Pulse jet systems are utilized to keep the filters of the dirt collection system particulate-free. The gathered material is removed and collected in drums. Zinc Zinc dirt is produced in the galvanizing procedure.

Rice Dirt Rice dust has very great as well as minute fragments that accumulate during my link the manufacturing of rice-based products. A dirt collection system is needed for the protection and also security of employees.